LiveFactory is an innovative suite of tools designed to empower your team to

improve machine productivity,

use your labour more efficiently,

and improve service levels.

Why use it?

Empower your staff to visualize bottlenecks, monitor production and react proactively, all of which directly benefit your bottom line.

Improve Service Levels by

Creating transparency through visual management

Addressing bottlenecks

Achieving your production plan

Improve Labour Productivity by

Improving labour utilization

Measuring Units/Labour hr

Accounting for non-productive labour hours

Improve Machine Productivity by

Improving start-up performance

Reducing line stoppages

Understanding capacity constraints

We’ve distilled years of lean manufacturing experience into an easy-to-use product to accelerate your lean manufacturing journey.

Our Easy-to-Use Product

Visualize and remove bottlenecks with SkyView

You need product on the shelf and a high service level. Often the bottleneck is before production even starts. LiveFactory’s SkyView Module is the visual management tool you’ve been waiting for.

Track each stage of the job from BOM fulfillment to quality release

See bottlenecks clearly with visual management

Act with transparency using our built-in electronic Kanbans

Insights provide reporting on on-time performance, job cycle times and late job paretos

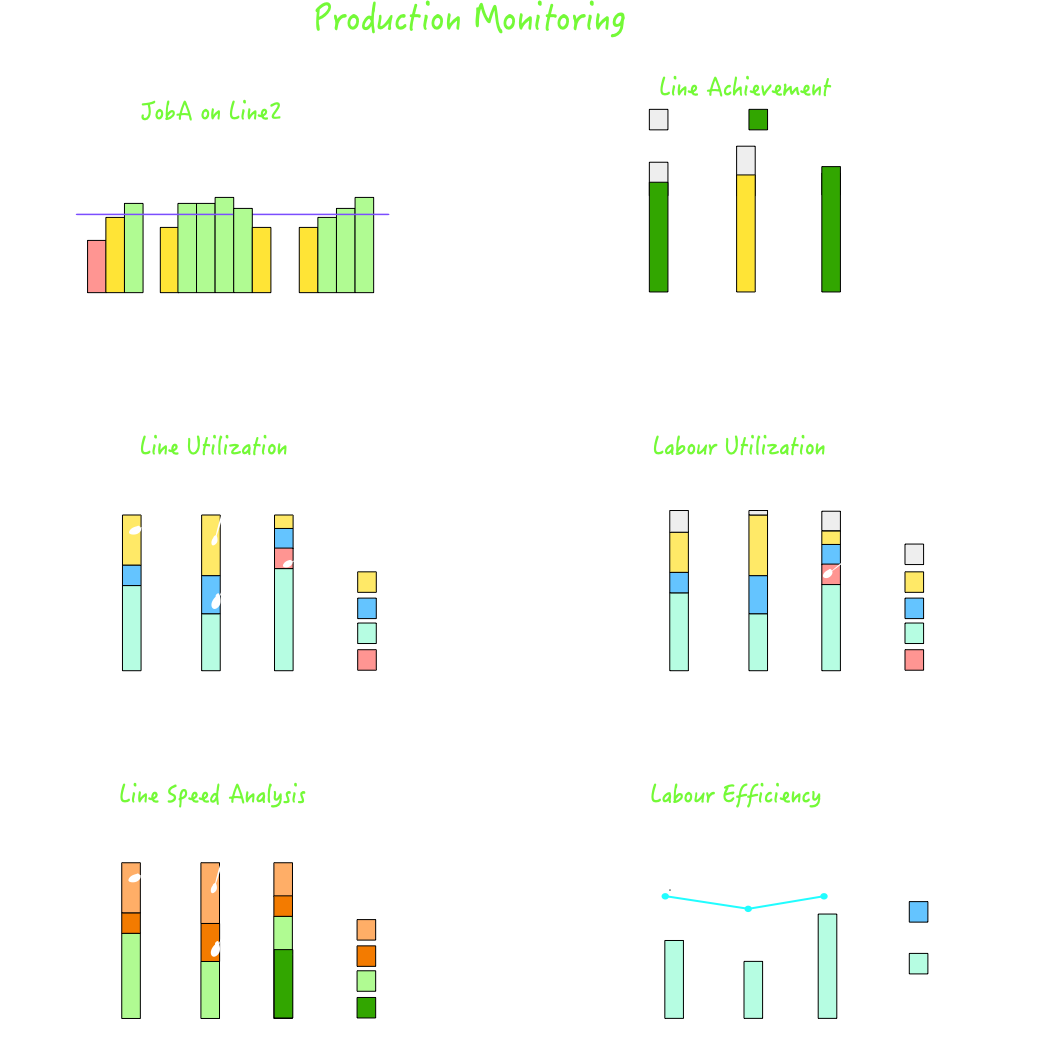

Monitor Production Line Performance

One of your highest variable costs are your wage costs. When your line stands due to a stoppage, your operators stand and your conversion costs are high. LiveFactory has a cloud-based Production Monitor that improves productivity by helping your team chase down production targets, see real-time insights and focus their improvement efforts.

Reliable, live stats on each production line put your supervisors in control

OEE analysis allows for pinpoint problem definition leading to better efficiencies

Stoppage analysis leads to increased availability

Team performance stats allow for better labour management and utilizations

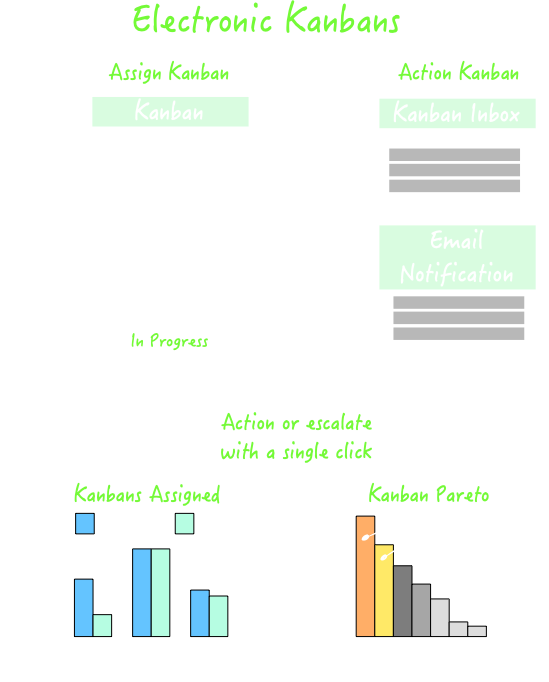

React Proactively with Electronic Kanbans

You need an easy way to communicate and remove critical Supply Chain and Production bottlenecks. Electronic Kanbans are integrated throughout LiveFactory to communicate tasks between teams that are traceable and actionable.

Easy to configure and intuitive to use

Kanbans are traceable and measurable creating clear accountability

Kanbans can be linked to Jobs providing live status updates that keeps everyone informed on the actions related to critical bottlenecks

Kanbans can be linked to email notifications for information or escalation

Pre-configured templates are customized to your operation to ensure that data is correctly entered and follows your companies SOPs

Kanban insights provide “bottleneck” reporting that can be used to measure and improve supply chain performance

Typical uses are for expediting missing BOM items, replenishing raw materials, logging quality issues and handling all other exceptions.

Benefits

We built the tools we needed to improve your operation

Designed by a Lean Six Sigma Black Belt engineer

Robust system designed and road tested in South Africa

Embeds lean manufacturing principles and tools to encourage productive behaviours to create a responsive manufacturing environment

Provides automatic focused insights to accelerate your lean improvement journey

Simple setup and launch leads to immediate impact

Cloud-based setup means only mains power and a LAN cable and a single IR sensor are

required for monitoring production lines

Clever UX design allows intuitive operation and easy training and onboarding

Option to integrate with your ERP system down the line

“We created LiveFactory from the ground up as an easy but powerful production monitoring solution. It’s not that there aren’t systems for this already, however we used our consulting experience to integrate lean principles directly into the product. By design, we promote efficient behaviour.”

Case Study

A manufacturer of over-the-counter medicines deployed LiveFactory in order to kick-start a lean manufacturing programme.

In order to minimise impact on the production team the deployment and training was staggered over a month, as the year end shut-down was approaching.

Immediate benefits included greater visibility of planned and actual volumes, leading to greater accountability among operators and more focused production meetings. Line Supervisors now have to account for their stoppages creating a culture of accountability and Maintenance has to prioritize fixes based on actual quantifiable production pain points.

Better understanding of the production environment and its constraints is leading to a more motivated and better aligned management team.

LiveFactory provided a reliable, complete data-set that provided a clear business-case to reconfigure a batch processing line to a single piece workflow process. After a few production runs on the new process, LiveFactory established the new achievable demonstrated capacity. As a result the planners were able to significantly increase sustainable production output levels.

Over a two month period LiveFactory was deployed, staff trained, and analysis generated that has improved operator accountability, supported a concrete step change in demonstrated capacity on one line, and built the team’s confidence to drive further improvements. Decisions are now backed up by data that is visible to everyone.

Testimonials

LiveFactory software fills the gap when you don’t have the staff maturity or skills.

Peter Kreft, CEO, CoMED Health

Over the past 3 years, LiveFactory has changed the way we look at our operational efficiency with its performance first philosopy . The real-time visibility into production and supply chain data has enabled our team to respond quickly to inefficiencies and drive continuous improvement. The LiveFactory/ Skyview platform has become an integral tool in how we carry out our daily operation with the Kanban system being used extensively beyond traditional material flow applications.

What stands out most is the incredible support from Salim and the team, who are always available to assist with troubleshooting or general queries whilst consistently going above and beyond to tailor the platform to the evolving needs of a modern manufacturing plant – this dedication makes it feel as if the LF team is an extension of our organization.

Yakeel Baruth, Industrial Engineer, Silveray Stationery Company (Bidvest Group)

LiveFactory has greatly improved communication amongst departments and improved relationships in the company.

Sharon Sithole, Production Supervisor, CoMED Health

Pricing

LiveFactory has a fundamentally different business model to other monitoring software

Pricing is per production line, with no limit on the number of users

Being cloud based, hardware and installations costs are substantially lower than competing platforms

Simple, clear pricing with a simple monthly service fee

FAQ

Will it work for my factory?

Yes. LiveFactory will work for any production environment where an IR sensor can be mounted to count items as they pass by.

Who owns the data?

You own your data and it is downloadable at any point as a CSV file.

Is it secure?

Yes. We follow industry best practice to protect your data.

Am I locked in?

No. We are confident in the quality our product and service, however you may cancel the service at any time with one months notice.

What countries is the LiveFactory service available in?

LiveFactory has been developed and deployed in factories in Johannesburg, South Africa. We are able to provide on-site installation, support and training in South Africa and the UK at present. For other countries, we courier monitoring units to you and provide web-based configuration, support and training.

Is there a way to try out LiveFactory before signing up?

Please enquire about a risk-free pilot deployment at no cost for a month. This allows you to evaluate the LiveFactory system on a single production line. At the end you can either return the device we provided or extend the service.

Do you provide Lean Manufacturing consulting?

Yes. This is available on-site in South Africa at present from an experienced black belt consultant who can mentor your teams to embed the LiveFactory culture and ensure you get the most value out of the system.